What is Polyurethane Open Cast Molding?

Open cast molding is a process whereby a liquid resin and a liquid curative are heated to a processing temperature by a trained plastic technician. The materials, while in a liquid state, are weighed in a precise ratio and added together in one container or batch.

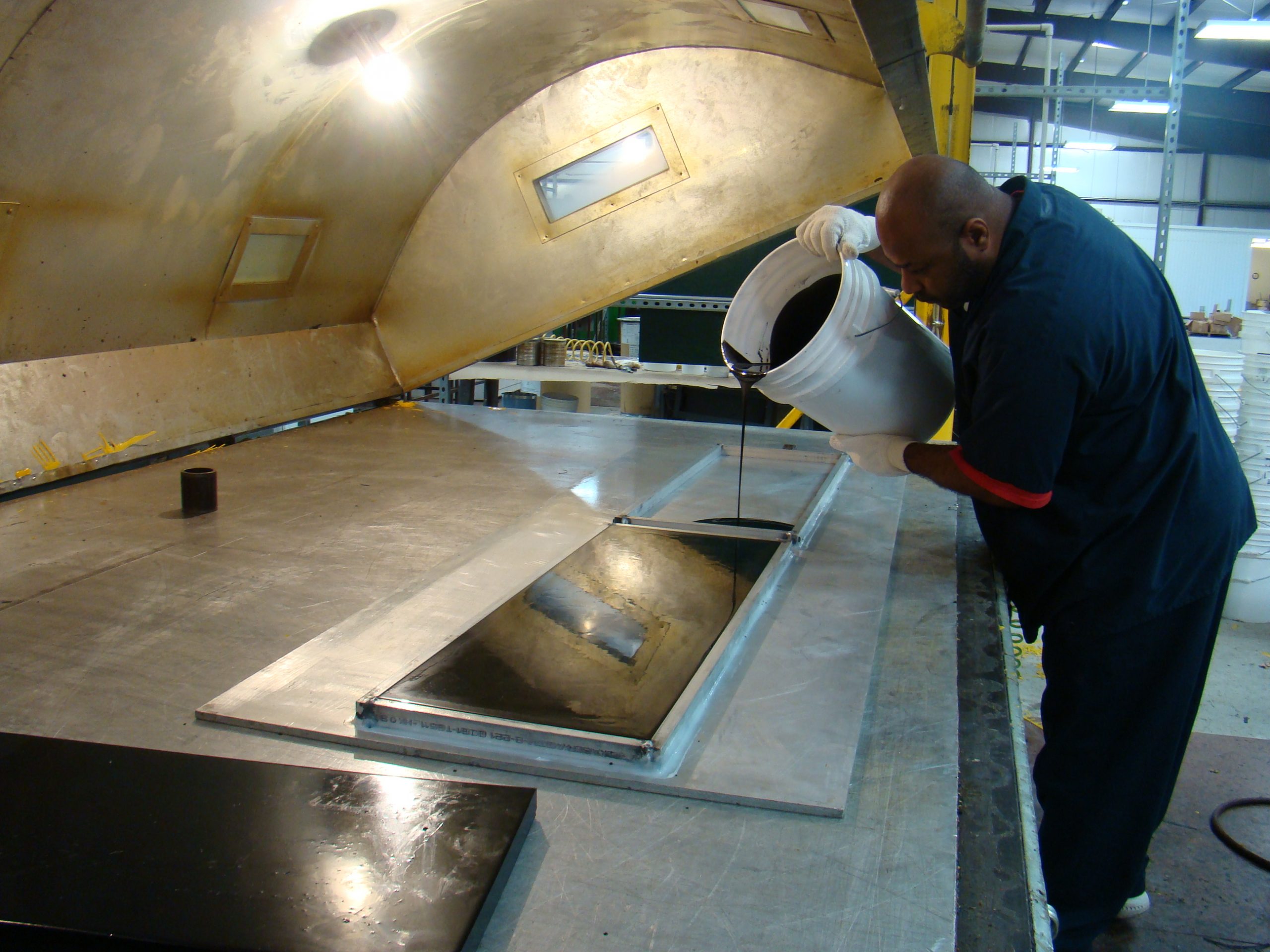

These are then mixed by hand as a chemical reaction begins to transform the liquid mixture into a solid. While the mixture is still in liquid form, it is poured into heated molds that are approximately the same temperature as the mixture, which is about 220F. Once the mixture solidifies, the finished part is ready to be removed from the mold.

Benefits of open cast molding vs molding by automated mixing:

- Variety of materials– Under automated mixing, a processor is usually limited to a certain number of materials or formulations, that can be used based on the number of tanks each machine has available. Open cast molding has no such limitation as any resin and curative combination can be processed under this technique.

- Short production runs– Automated mixing works best when a processor has a large volume of parts to produce or a large amount of material to dispense. Shorter production runs or parts with less material weight requirements can generally be processed more cost-effectively under the open cast process, as the amount of material needed is controlled better by this process.

- Additives-Formulations that require additives, such as powders or thick pastes, can clog filters in a mixing machine or settle in batch tanks in the same machine. Under open cast molding, additives can be mixed without this concern, as these are manually added with the resin and curative.

For more than 50 years, ESCO Plastics has been committed to manufacturing high-quality, reliable, and affordable molded urethane products for manufacturers worldwide. Our team of expert engineers and trained technicians are focused on providing only the best and most consistent cast urethane parts. To discuss your product requirements with an ESCO Plastics engineer, call 281-443-3710.