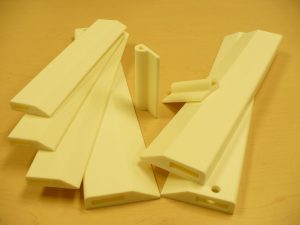

Custom Polyurethane Scrapers

Custom urethane scrapers, also known as polyurethane scraper blades, are used in many industries and across OEM equipment types. At ESCO Plastics, we manufacture a wide range of durable scraper blades that are formed and fabricated to be flexible and withstand constant use, extreme conditions, abrasive materials, and harsh chemicals.

Common Custom Urethane Scraper Applications

- Urethane Conveyor Belt Scrapers help to remove debris such as rock, gravel, sand, and other materials processed on conveyors, that can cause material build-up. Urethane Belt Scrapers are typically located at the exit of a conveyor belt system, to help remove or loosen any foreign objects like rocks and debris.

- Urethane Mud Scrapers are wear-resistant and offer outstanding physical properties, like their noteworthy ability to resist abrasion caused by friction, as well as deterioration triggered by corrosion and chemicals.

- Urethane Wiper Blades and Urethane Scraper Blades are common in many industries and across equipment types. They are flexible, non-corrosive, and resistant to chemicals — ideal for demanding conditions with persistent service requirements.

Durometer hardness of polyurethane scraper blades ranges from 70A to 70D depending on the flexibility needed for the application. Urethane will typically outlast rubber 10 to 1 under abrasive conditions and will last three times longer than the average metal scraper.

The ESCO Plastics team is ready to customize polyurethane scraper blades to your requirements, contact us at 281-443-3710.